Applications of Bitumen:

Although modern bitumen products are of very high quality, their primary uses remain similar to those of the past: waterproofing, adhesion, and protective coatings. Today, bitumen has more than 250 different applications across agriculture, construction, industry, road building, and other sectors. This section examines the applications of different types of bitumen.

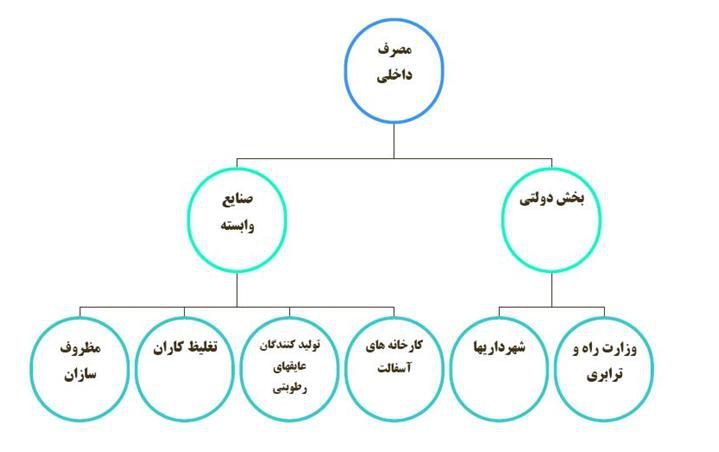

The majority of bitumen produced in Iran and worldwide, often referred to as natural bitumen, is used in road construction, where it acts as a binder in asphalt. The second-largest application is in building construction, primarily as a roofing and waterproofing material.

Estimates indicate that global bitumen consumption reaches approximately 102 million tons per year, of which around 85% is used in road construction. Among these, 60/70 penetration grade bitumen is the most commonly applied. Over 10% of natural bitumen is used in construction and as a waterproofing material, while the remainder is used for various purposes such as sealing, insulation, and pipe coating.

Key Applications of Bitumen:

۱)Bitumen and Emulsion Applications in Road and Airport Pavements:

1. Surface overlays

۲. Penetration macadam

۳. Cold machine mixes

۴. Sealing with slurry mixtures

۵. Surface coatings

۶. Reinforcement coatings

۷. In-situ soil stabilization

۸. Dust control

۲) Petroleum Mulches – Usage Methods:

۱. Stabilization of sandy soils

۲. Protection of airports and facilities

۳. Construction mulches

۴. Agricultural mulches

۵. Artificial rain production

۶. Road and railway mulches

7. Insulation mulches

۳) Bitumen as Protective Coatings for Concrete Sewer Pipes

۴) Bitumen in Polymer-Modified Waterproofing Systems